Industrial Waste Water Treatment-- Tailored Solutions for Effective Wastewater Treatment

Industrial Waste Water Treatment-- Tailored Solutions for Effective Wastewater Treatment

Blog Article

Secret Strategies in Hazardous Waste Water Treatment Procedures

The treatment of industrial wastewater is a crucial element of ecological administration, including a series of strategies made to reduce the influence of contaminants. From the basic physical approaches that separate solids to the innovative chemical and biological procedures that target details toxins, each strategy plays a vital function in accomplishing water quality criteria. Developments in innovations such as membrane purification and advanced oxidation procedures use cutting-edge solutions for improving therapy efficacy. Recognizing how these techniques interconnect and their ramifications for sustainability elevates essential concerns about the future of wastewater management in market.

Physical Treatment Techniques

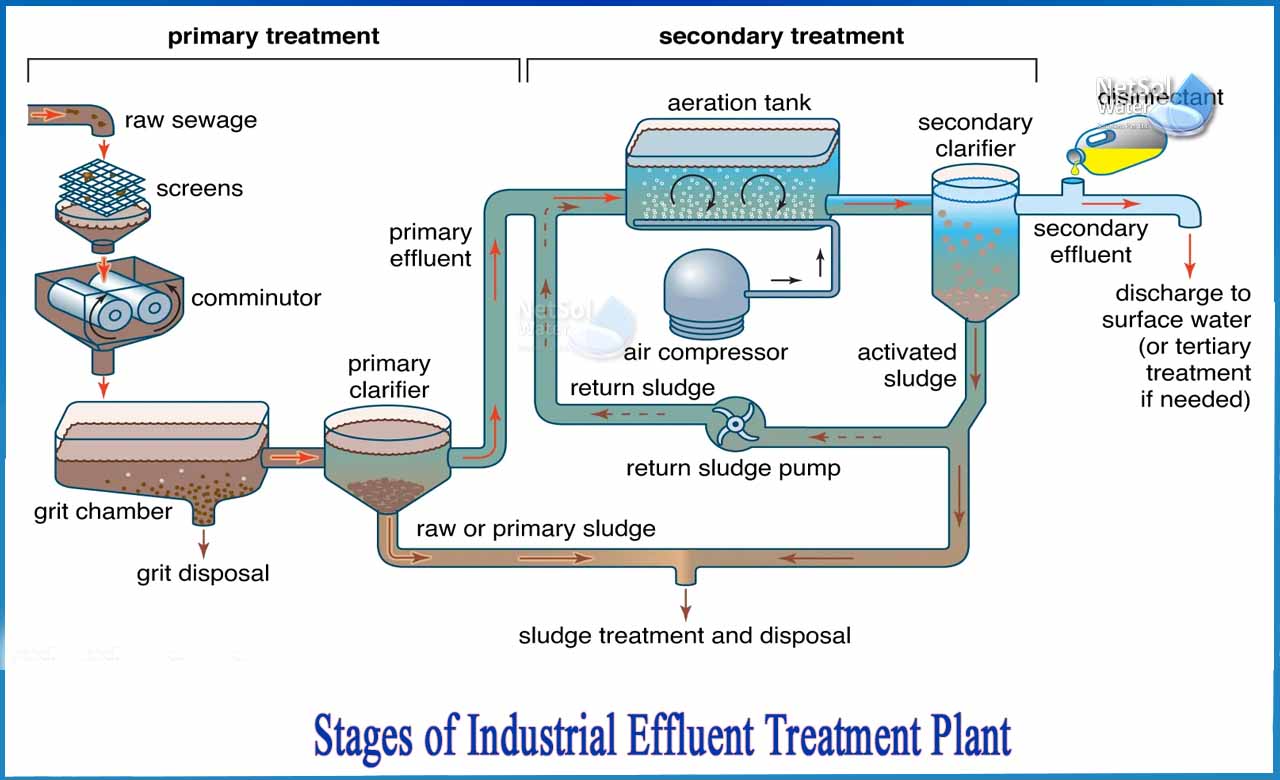

Exactly how effectively can physical therapy approaches address the intricacies of commercial wastewater? Physical treatment approaches play an essential function in the preliminary phases of wastewater administration, concentrating largely on the removal of solids and huge particulates. Strategies such as filtration, sedimentation, and flotation protection are necessary for minimizing the concentration of suspended solids, thereby enhancing the effectiveness of succeeding treatment procedures.

Sedimentation includes the gravitational settling of solids, permitting for the splitting up of larger materials from the wastewater. This method is especially reliable in making clear water prior to chemical or biological treatments.

Furthermore, flotation approaches, which utilize air bubbles to raise put on hold solids to the surface for elimination, are efficient in dealing with wastewater with high focus of fats, oils, and greases. Overall, physical therapy techniques act as a critical primary step in the thorough monitoring of industrial wastewater, guaranteeing that the load on succeeding treatment stages is decreased and enhancing total treatment efficacy.

Chemical Therapy Methods

While physical treatment methods prepared for reliable wastewater monitoring, chemical treatment techniques are vital for dealing with the extra intricate impurities often discovered in industrial effluents. These techniques utilize different chemical agents to precipitate, neutralize, or oxidize dangerous compounds, guaranteeing an extra detailed removal of toxins.

One typical approach is coagulation and flocculation, where chemical coagulants such as aluminum sulfate or ferric chloride are included in promote the gathering of put on hold fragments. This process improves solid-liquid separation, decreasing turbidity and improving water high quality. Additionally, neutralization procedures are utilized to change the pH of wastewater, using bases or acids to counteract acidic or alkaline streams, respectively.

Oxidation-reduction responses play a crucial duty in derogatory natural impurities and virus. Chemical oxidants like hydrogen, chlorine, or ozone peroxide are used to break down intricate natural substances, making them less dangerous or a lot more naturally degradable. In addition, advanced oxidation processes (AOPs) combine numerous oxidation methods to boost contaminant elimination effectiveness.

Biological Therapy Processes

The efficiency of wastewater treatment is considerably improved by organic therapy procedures, which harness the all-natural metabolic tasks of bacteria to decompose raw material and get rid of pollutants. Industrial Waste Water Treatment. These procedures primarily entail cardio and anaerobic food digestion, each customized for specific kinds of wastewater

Aerobic therapy processes make use of oxygen to sustain microbial development, promoting the breakdown of natural pollutants right into carbon dioxide and water. Usual approaches consist of turned on sludge systems, where oygenation storage tanks assist in the blending of wastewater with microorganisms, and flowing filters, which urge biofilm development on media surface areas.

On the other hand, anaerobic therapy processes happen in the absence of oxygen, making use of anaerobic germs to decompose raw material, leading to biogas production, a renewable resource resource. Anaerobic digesters are frequently used in commercial setups for this objective, properly lowering the quantity helpful site of sludge while creating important biogas.

The option of an organic treatment method relies on wastewater qualities, treatment objectives, and regulatory criteria. The integration of biological procedures in wastewater therapy not only enhances toxin elimination performance but additionally advertises sustainability by reducing chemical use and supporting resource recuperation.

Advanced Oxidation Processes

Typical AOP techniques include Fenton's ozonation, photocatalysis, and reagent. Fenton's reagent, a combination of hydrogen peroxide and ferrous iron, militarizes the development of hydroxyl radicals, making it effective for dealing with wastewater having phenolic substances and other stubborn compounds. Ozonation makes use of ozone as a powerful oxidant, efficient in weakening a large range of organic pollutants while at the same time sanitizing the effluent. Photocatalysis employs light-activated drivers, such as titanium dioxide, to enhance oxidation responses and eliminate pollutants.

AOPs supply a number of advantages, consisting of decreased sludge manufacturing and the capability to treat wastewater with high focus of natural toxins. Nevertheless, the implementation of AOPs calls for mindful factor to consider of operational parameters and cost-effectiveness, ensuring that these advanced methods are suitably integrated into existing wastewater therapy systems.

Membrane Layer Filtering Technologies

Microfiltration works for removing put on hold solids and bacteria, while ultrafiltration targets smaller organic particles and infections. Nanofiltration bridges the space between ultrafiltration and reverse osmosis, efficiently removing divalent ions and organic substances. Reverse osmosis supplies the greatest degree of purification, utilized primarily for desalination and eliminating mono-valent ions.

Membrane layer innovations supply numerous advantages, consisting of reduced energy intake contrasted to standard treatment approaches, modular layout for scalability, and the possibility for water healing and reuse. Nevertheless, obstacles such as membrane fouling and the need for routine maintenance must be addressed to ensure system efficiency. Generally, membrane layer filtering innovations stand for an important element of contemporary industrial wastewater treatment techniques, promoting sustainability and source conservation in water administration.

Conclusion

To conclude, commercial wastewater treatment employs a varied range of methods, consisting of physical, chemical, biological, and progressed methods. Each technique plays an important function in properly resolving numerous pollutants, boosting water quality, and advertising source sustainability. The assimilation of these methods fosters a thorough therapy strategy, making certain that industrial effluents meet regulatory requirements while decreasing environmental influence. Proceeded innovations in these approaches will certainly additionally enhance the effectiveness and efficiency of wastewater treatment procedures in commercial settings.

The therapy of industrial wastewater is a critical facet of ecological administration, involving an array of methods made to reduce the impact of impurities.Exactly how successfully can physical therapy methods resolve the complexities of commercial wastewater?Advanced oxidation procedures (AOPs) stand for a cutting-edge approach in commercial wastewater therapy, designed to properly deteriorate natural toxins that are read here commonly resistant to traditional therapy methods (Industrial Waste Water Treatment).In verdict, industrial wastewater treatment uses a diverse array of techniques, consisting of physical, chemical, organic, and progressed approaches. Continued developments in these methodologies will certainly even more improve the efficiency and efficiency of wastewater treatment procedures in commercial settings

Report this page